How to Measure the Neck Size of Your Bottle or Cap

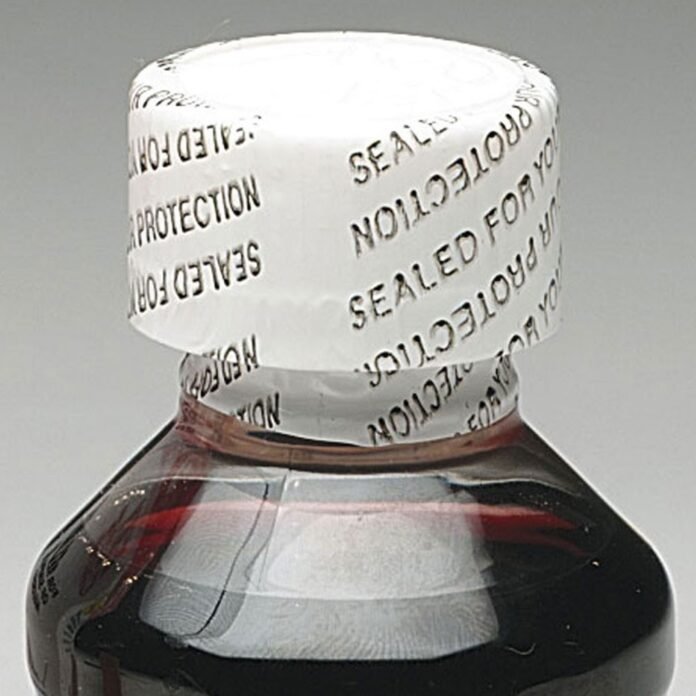

Understanding the precise neck size of bottles and caps is essential across various industries, including manufacturing, packaging, and even everyday household use. At Shree Tirupati Balaji, we emphasize the importance of accurate measurements to ensure that our clients receive high-quality closures, such as the PVC Printed Heat Shrink Cap Seal, that fit perfectly and maintain product integrity. The neck size, including the diameter and thread configuration of the bottle’s opening where closures like caps or pumps are applied, plays a crucial role in ensuring a snug fit for the PVC Printed Heat Shrink Cap Seal. This measurement ensures that the closure fits correctly, preventing leaks and ensuring the contents are securely sealed. Different products require specific neck sizes to maintain functionality and safety standards.

Tools Needed

Before you begin measuring, gather the necessary tools: a caliper or ruler for measuring diameter and a thread gauge (optional) to determine thread type and pitch. These tools are crucial for obtaining accurate measurements, which are vital for selecting compatible closures like the PVC Printed Heat Shrink Cap Seal and ensuring proper sealing.

Step-by-Step Guide to Measure Neck Size

Step 1: Measure the Diameter

Start by measuring the external diameter of the bottle neck using a caliper or ruler. Place the measuring tool around the widest part of the neck and record the measurement in millimeters (mm). For closures that require it, also measure the inner diameter by placing the caliper inside the neck. This step ensures you have both external and internal measurements for accurate fitting of the PVC Printed Heat Shrink Cap Seal.

Step 2: Determine Thread Specifications (if applicable)

If your closure, such as the PVC Printed Heat Shrink Cap Seal, requires a threaded neck, use a thread gauge to determine the type of thread (e.g., continuous thread, lug finish) and the thread pitch (threads per inch or millimeter). This information ensures that the PVC Printed Heat Shrink Cap Seal screws on properly and securely, preventing leaks or accidental opening.

Step 3: Record Your Measurements

Document all measurements accurately, including external and internal diameters, thread type, and thread pitch. Keeping detailed records helps when ordering closures like the PVC Printed Heat Shrink Cap Seal or referring to specifications in the future. Accurate documentation ensures that you can confidently select compatible closures for your bottles.

Step 4: Consider Compatibility

When choosing closures, ensure they are compatible with the neck size and thread specifications you’ve measured, specifically for products like the PVC Printed Heat Shrink Cap Seal. Different closures (caps, pumps, sprayers) require specific neck finishes to function correctly. Also, consider the material compatibility between the PVC Printed Heat Shrink Cap Seal and the bottle contents (e.g., chemicals, food products) to maintain product integrity and safety.

Step 5: Use Online Resources for Verification

For additional verification, consult online resources provided by bottle and closure manufacturers. At Shree Tirupati Balaji, we provide comprehensive guides and specifications to help you verify your measurements and ensure compatibility with our range of high-quality closures, including the PVC Printed Heat Shrink Cap Seal. These resources can also provide insights into industry standards and best practices for selecting closures based on neck size and thread type.

Conclusion

Measuring the neck size of your bottle or cap is a straightforward process when approached systematically with the right tools and understanding. By accurately measuring the diameter and identifying thread specifications, you ensure proper closure fitment and functionality, especially crucial for closures like the PVC Printed Heat Shrink Cap Seal. This knowledge not only facilitates efficient packaging solutions but also helps maintain product quality and safety standards across various applications. At Shree Tirupati Balaji, we are committed to providing solutions that meet your packaging needs with precision and reliability, including our range of PVC Printed Heat Shrink Cap Seals.

By following these steps and guidelines, you can confidently measure and verify the neck size of any bottle or cap, ensuring seamless compatibility with closures like the PVC Printed Heat Shrink Cap Seal and optimal performance in your packaging solutions.