Plastic bottles are a ubiquitous part of daily life, used for everything from water and juice to household cleaners. Despite their convenience, many of us have experienced the frustration of a leaking bottle. Whether it’s a slow drip or a full-blown spill, understanding the reasons behind these leaks can help prevent them. Here are the five most common reasons why plastic bottles leak and how you can avoid them.

1. Poor Manufacturing Quality

One of the primary reasons plastic bottles leak is due to poor manufacturing quality. Bottles can have defects that aren’t always visible to the naked eye. These defects can include thin spots in the plastic, small holes, or improperly sealed seams. During the manufacturing process, if the machinery is not calibrated correctly or if the quality control measures are inadequate, these defects can slip through and cause leaks.

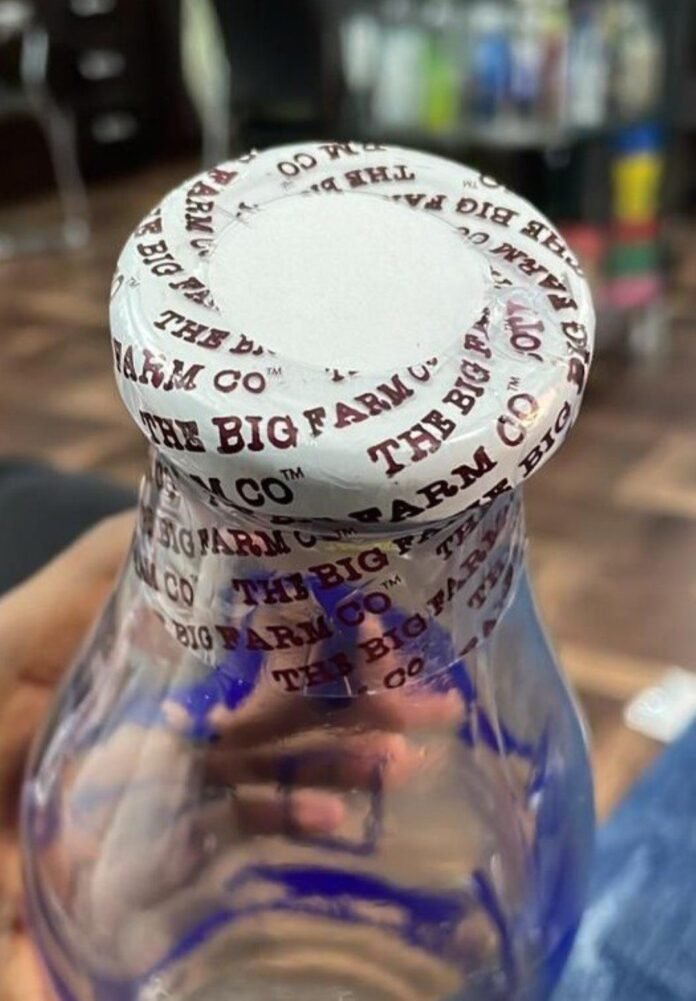

To avoid this issue, always check the integrity of a bottle before use. Squeeze the bottle lightly to see if there are any weak spots or signs of damage. Additionally, purchasing bottles from reputable brands can reduce the likelihood of encountering manufacturing defects. At Shree Tirupati Balaji, we ensure stringent quality control for all our products, from Milk Bottle Neck Seal to PVC Shrink Labels and Dual Seal Caps, guaranteeing durability and reliability.

2. Improper Cap Sealing

Another common cause of leaks is improper cap sealing. When the cap isn’t screwed on correctly or tightly enough, it can leave gaps where liquid can escape. This can happen if the threads on the bottle or the cap are damaged, if there is debris on the threads, or if the cap is simply not designed well.

To prevent leaks from improper sealing, always ensure the cap is tightly secured. Check the threads on both the bottle and the cap for any signs of damage or dirt. If you notice any issues, clean the threads thoroughly or replace the cap if it’s damaged. A well-sealed cap should fit snugly and create a secure barrier to prevent leaks. Shree Tirupati Balaji’s extensive range of products, including our Milk Bottle Neck Seals and Dual Seal Caps, are designed to provide the best sealing solutions, ensuring your bottles remain leak-proof.

3. Temperature Fluctuations

Temperature fluctuations can cause plastic bottles to expand and contract, leading to leaks. When a bottle is exposed to high temperatures, the plastic can soften and change shape, compromising the seal between the cap and the bottle. Conversely, cold temperatures can make the plastic brittle, increasing the risk of cracks and leaks.

To mitigate this issue, store plastic bottles in a stable environment away from extreme temperatures. Avoid leaving bottles in hot cars, direct sunlight, or freezing conditions. If a bottle has been exposed to significant temperature changes, inspect it for any signs of deformation or damage before use. Shree Tirupati Balaji’s Milk Bottle Neck Seals are designed to withstand various temperature ranges, providing consistent performance and preventing leaks.

4. Overfilling the Bottle

Overfilling a plastic bottle can also lead to leaks. When a bottle is filled beyond its capacity, it can put pressure on the cap and the bottle walls, causing them to bulge and create gaps. This is especially true for carbonated beverages, where the buildup of gas adds additional pressure inside the bottle.

To prevent leaks from overfilling, always fill bottles to the recommended level, usually indicated by a fill line on the bottle. For carbonated drinks, leave extra space at the top to allow for gas expansion. Ensuring the bottle is not overfilled will help maintain a proper seal and reduce the risk of leaks. Shree Tirupati Balaji’s PVC Shrink Sleeves offer an excellent solution for labeling and securing bottles without compromising on capacity. Our Milk Bottle Neck Seals are particularly effective in maintaining a secure closure, preventing leaks even under pressure.

5. Wear and Tear

Over time, plastic bottles can experience wear and tear from regular use. Repeated opening and closing of the cap, exposure to cleaning agents, and physical impacts can all degrade the integrity of the bottle. Small cracks, worn-out threads, and weakened plastic can develop, making the bottle more prone to leaking.

To extend the life of your plastic bottles, handle them with care. Avoid dropping or squeezing them too hard, and be gentle when opening and closing the cap. If you notice any signs of wear, such as cracks or weakened areas, it’s best to replace the bottle. Regularly inspect your bottles for damage and retire them when they show significant signs of wear. Shree Tirupati Balaji manufactures high-quality PVC Shrink Labels and Dual Seal Caps that are designed to last, ensuring your bottles remain in excellent condition for longer periods.

Conclusion

Leaking plastic bottles can be a nuisance, but understanding the common causes can help you prevent them. By paying attention to manufacturing quality, ensuring proper cap sealing, avoiding temperature extremes, not overfilling, and watching for wear and tear, you can keep your plastic bottles leak-free and extend their usability. Taking these simple precautions can save you from the hassle and mess of unexpected leaks.

For all your sealing and labeling needs, trust Shree Tirupati Balaji, a leading manufacturer of PVC Shrink Labels, PVC Shrink Sleeves, Seal Tags, Dual Seal Caps, Milk Bottle Neck Seals, and more. Our products are crafted with the highest quality standards to ensure your bottles remain leak-proof and secure.